The Innovation Solution Behind Our Severe Duty Chains for CAT 623 Scrapers

Today, CAT offers similar heavy-duty option chains for 623 scrapers, but that hasn’t always been the case.

Nearly 20 years ago, Cutting Edge Supply helped to fortify the wear life of the 623 scraper chains with an innovative twist. Bill Masters, the equipment manager at Schwab in the early 2000s, was running a large fleet of scrapers through the Arizona desert. The scraper fleet was encountering a mix of rock and sand, and the CAT OEM chains were averaging around 2,500 hours of lifetime. Bill hit up his sales rep at Cutting Edge, Chris Barnes, to see if Cutting Edge could somehow fabricate a heavier chain that would extend wear life.

Barnes took the issue to then-scraper parts manager Hal Baldwin. A scraper guru, Hal quickly pointed out that both the 623 and the thicker/heavier 633 chains had the same chain pitch (4.063” from pin-to-pin). Since the pitch was the same, it was possible to use the 633 thicker chain rails on the rollers and other parts of the 623. However, this would require a change to the attachment links where the flights connect as the bolt pattern varies on flights from 623 to 633. Within just a few days, Baldwin had the drawing completed for the special flight attachment links.

Masters loved the idea and the first ever 623 Severe Duty chains were sent to a special production run.

Three months later, Masters began testing the chains on several of his scraper machines. The rest is history with thousands of sets sold since.

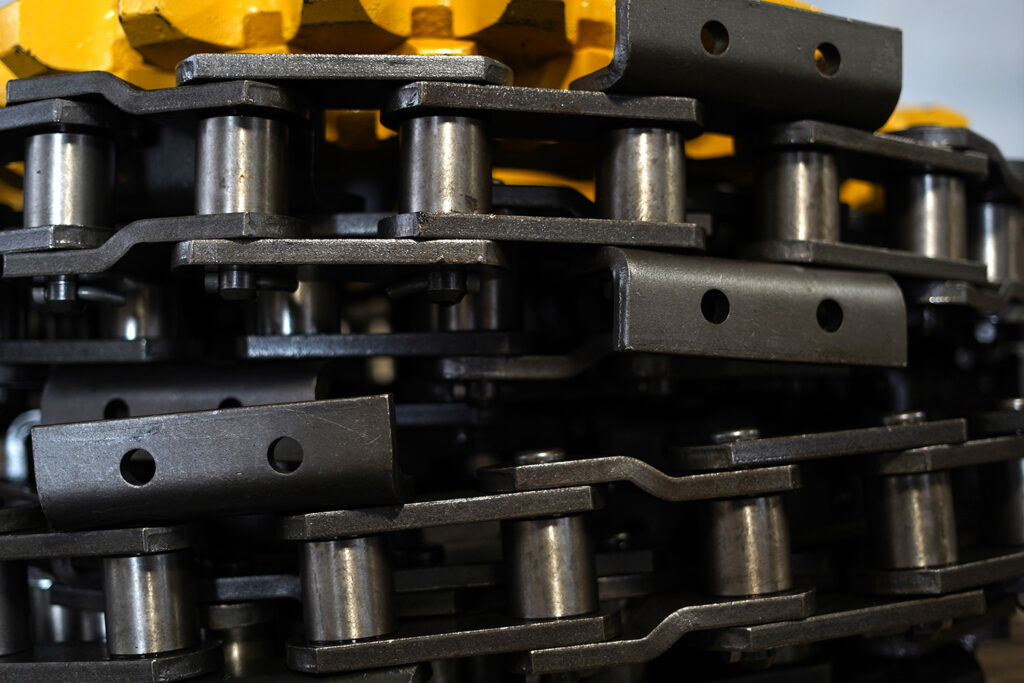

Cutting Edge Supply Severe Duty (HD) chains for CAT 623 Elevated Scrapers run with standard sprockets and any brand of 623 flights. An increased side bar thickness defends against wear and binding due to rocky or sandy material. They are made with all heat-treated components with added wear-chrome for the rollers and pins. A keeper pin on every section makes for easy replacement and repair.

Most of the data over the years supports a sprocket flip or change around 3,000 hours. Customers can then run the chains until destruction, which has averaged over 5,000 hours. One customer even had a 623G that went over 7,500 hours with two sprocket changes and never a single broken link.