Serrated Edges Extend Clamshell Bucket Wear Life

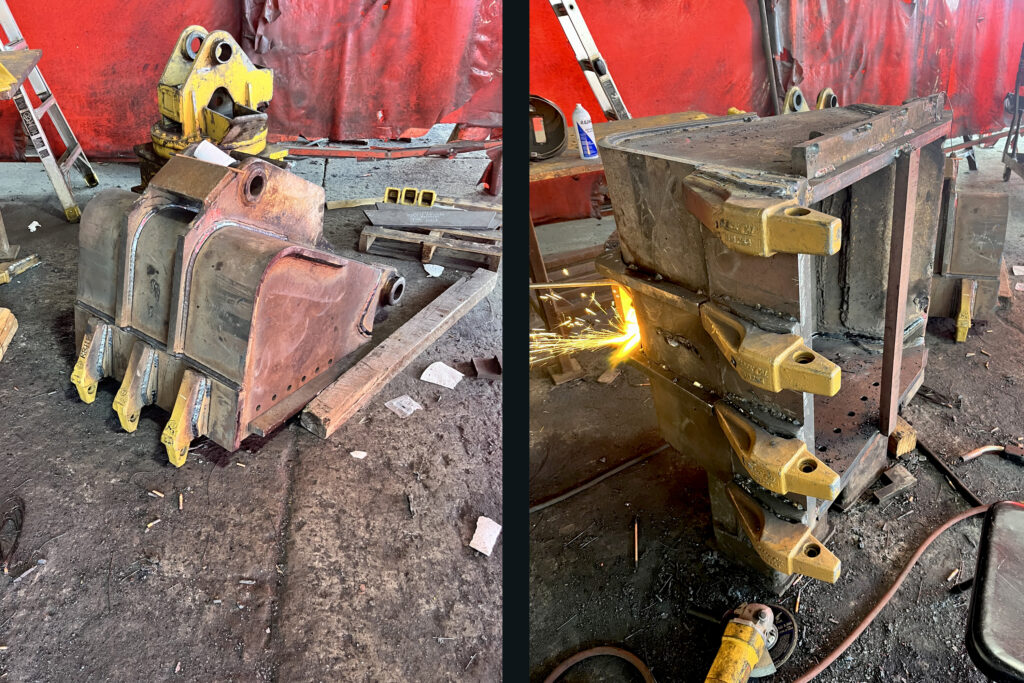

Our Colton shop helped to completely revitalize and upgrade this Clamshell bucket for Hirschi Masonry, a Nevada-based construction company.

Used to place rocks on a retaining wall in a new residential housing development, the two buckets came in with extreme wear on the vertical edges of the buckets, leading Cutting Edge Supply Machine & Repair Manager Eric Jacops to seek alternative options.

“The leading edges were taking the most abuse and wearing out much faster than any other part of the unit, so I wanted to come up with something that could be easily replaced as it wore out so they would not have to down the machine and pay thousands of dollars every time,” said Jacops.

“The reason for going with serrated edges rather than straight/smooth edges was to provide extra gripping power for grabbing the large rocks that they maneuver with these clam units.”

With the serrated setup, the edges can be flipped and rotated so that all four corners contribute to wear life and no part of the edge goes unused. The shop added an extra set of holes in the sides so that the pattern can be reversed as needed.

This approach cut costs from thousands to hundreds for the edges, as well as reduced down time for the unit from weeks to hours!

The Colton shop replaced the lips of both buckets with Strenx 700 material and installed new CAT style J250 teeth and adapters. The side plates were replaced with a more robust one-piece design, while the bottom and back of the buckets were replaced with a thicker, formed section of Hardox 450. The crew also built-up and machined the bores, and then reassembled the unit with all-new bushings and pins, supplied by our Chrome Craft division in Sacramento.

- The bucket originally came in with severely worn-out edges!