High Strength Steel

As an SSAB (Hardox®, Strenx®, Duroxite® and Armox®) dealer, Cutting Edge Supply stocks the highest quality, abrasion resistant alloy steel on the planet.

We offer many grades of wear plate and high strength steel plate in a variety of thicknesses (from 3mm to 4”) that we can cut to your specifications. Our sales team can also help you choose the right plate for your application.

Certified Hardox® Shop

Cutting Edge Supply is also a certified Hardox Wearparts expert shop, a distinction appointed to us by SSAB Hardox.

As a Hardox Certified Shop, we are part of a global network of select parts manufacturers that strive to provide only the highest quality wear parts made from the toughest and strongest steels in the world. Wear parts made from Hardox deliver precision parts and value-added wear life.

With our fully operational production plant, Cutting Edge Supply can form and fabricate steel to match a sample, drawing or template, as well as tackle any welding repairs you might need.

Hardox wear plate is the world's leading abrasion-resistant (AR)steel. Hardox is hard through and through, from the surface deep down to its core, giving you extended service life and high productivity in the most challenging environments.

WearCalc Mobile App

Download the Hardox WearCalc app and calculate the increased service life and payload when upgrading to Hardox wear plate.

Hardox® HiTuf

For the thickest structural wear applications

Hardox HiTuf is an abrasion-resistant steel plate with guaranteed impact toughness of 40 J at -40°C (-40°F).

Hardox HiTuf steel with a nominal hardness of 350 HBW makes a perfect choice for thick plate applications demanding extreme toughness and structural properties. In many cases, it can replace castings or cast parts. It is commonly used as a structural wear part for thick base edges for large buckets and mining shovels, demolition excavator breaker tools and dozer ripper shanks.

| Product | Thickness Range (in) | Typical Hardness (HBW) |

|---|---|---|

| Hardox HiTuf | 2" - 4-1/2" | 310-370 |

Hardox® 450 and Hardox® 500 Tuf

Wear steels with structural properties

Hardox 500 Tuf is the world’s hardest wear plate that still maintains structural properties. It delivers high strength, high hardness and guaranteed toughness in a single wear plate – a truly outstanding material for the most demanding applications.

Hardox 500 Tuf has proven itself worldwide in truck and tipper bodies, material containers, mining hoppers, buckets and other attachments, agricultural equipment, liners and wear parts. Thanks to its toughness, it can even perform as a structural material in heavy-duty equipment and hold up in freezing conditions. Hardox 500 Tuf combines the best properties from both Hardox 450 and Hardox 500. It’s your go-to wear plate with no real competition on the market.

Hardox 450 has a solid reputation as a highly versatile, abrasion-resistant steel that also has structural properties. With an extra 50 HBW hardness over the industry standard AR 400 grades, it provides additional wear resistance for an extended service life. The hardness also increases the steel’s strength, with better dent resistance as a result. The high toughness in cold conditions ensures that equipment can take impact forces without compromising its structural integrity.

| Product | Thickness Range (in) | Typical Hardness (HBW) |

|---|---|---|

| Hardox 450 | 2" - 4-1/2" | 390 - 475 |

| Hardox 500 Tuf | 3/16" - 1-1/4" | 475 - 505 |

Hardox® HiAce

for wear resistance in acidic environments

Hardox HiAce is a corrosion-resistant wear steel that helps to meet the challenges of acidic and corrosive wear environments found in garbage trucks, containers and recycling facilities, paper and sawmill environments, waste-to-energy plants and biomass facilities, and in ore mining and other processing industries.

Hardox HiAce features the same excellent wear properties as Hardox 450, with a nominal hardness of 450 HBW.

| Product | Thickness Range (in) | Typical Hardness (HBW) |

|---|---|---|

| Hardox HiAce | 3/16" - 1" | 425-475 |

Hardox® 500 and Hardox® 550

for challenging wear conditions

These abrasion-resistant steels are targeted at severe wear applications requiring limited structural performance.

Hardox 500 has a nominal hardness of 500 HBW for long service life while maintaining good processability and toughness. Hardox 500 is used in applications such as non-formed liner plates, grizzly bars, wear strips and other wear parts in wear-intense industries.

Hardox 550 has a nominal hardness of 550 HBW and toughness close to Hardox 500. It gives higher wear resistance, but not at the expense of crack integrity. Hardox 550 offers wear life improvements when replacing lower hardness steel grades or manganese steels. Typical applications include non-formed liner plates for crushers, chutes and other processing equipment.

| Product | Thickness Range (in) | Typical Hardness (HBW) |

|---|---|---|

| Hardox 500 | 1/8" - 3" | 450 - 540 |

| Hardox 550 | 3/8 - 2" | 525 - 575 |

Duroxite® 100

Duroxite products are designed for your most extreme wear situations with abrasion, impact, heat, metal-to-metal and erosion wear.

Duroxite fights wear for a long time thanks to its unique guaranteed wear properties, maintained down to 75% of the overlay thickness, and thus making it your hardest and longest wearing plate option. Duroxite is the natural choice for industries such as quarry, mining, cement, asphalt, crushing, steel mills, recycling and many other areas where abrasive materials require extremely hard surfaces.

One Hardox Customer Case Study showed that an open pit copper mining company experienced a 56% increase in service life on an electric shovel by using a Duroxite liner package.

| Product | Thickness Range (in) | Typical Hardness (HBW) |

|---|---|---|

| Duroxite 100 | 1/2" total, 3/4" total or 1" total | 600-700 |

Duroxite Fights Wear, Guaranteed

Duroxite overlay products come with guarantees that are unique for the overlay market.

When you, for example, order ½” thickness Duroxite, it is made of ¼” overall on a ¼” steel baseplate, and you know that this is the true ratio you will get within ±10%. This is consistent throughout each plate.

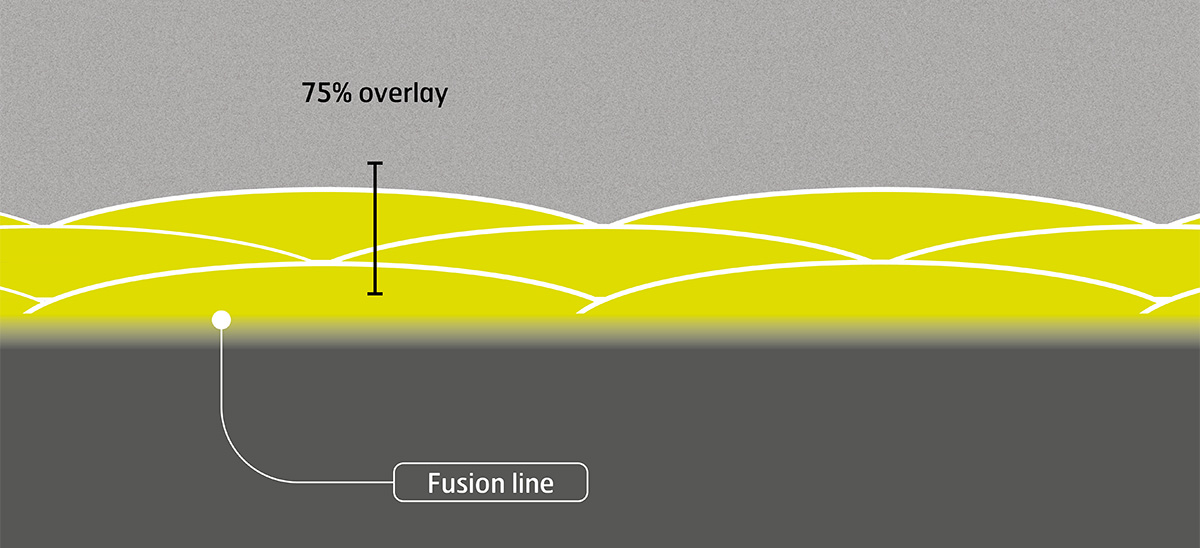

The wear properties are also guaranteed down to 75% of the hardfacing layer’s thickness as opposed to just the surface of the layer. The remaining 25% is the transition layer necessary to maintain good bonding to the baseplate.

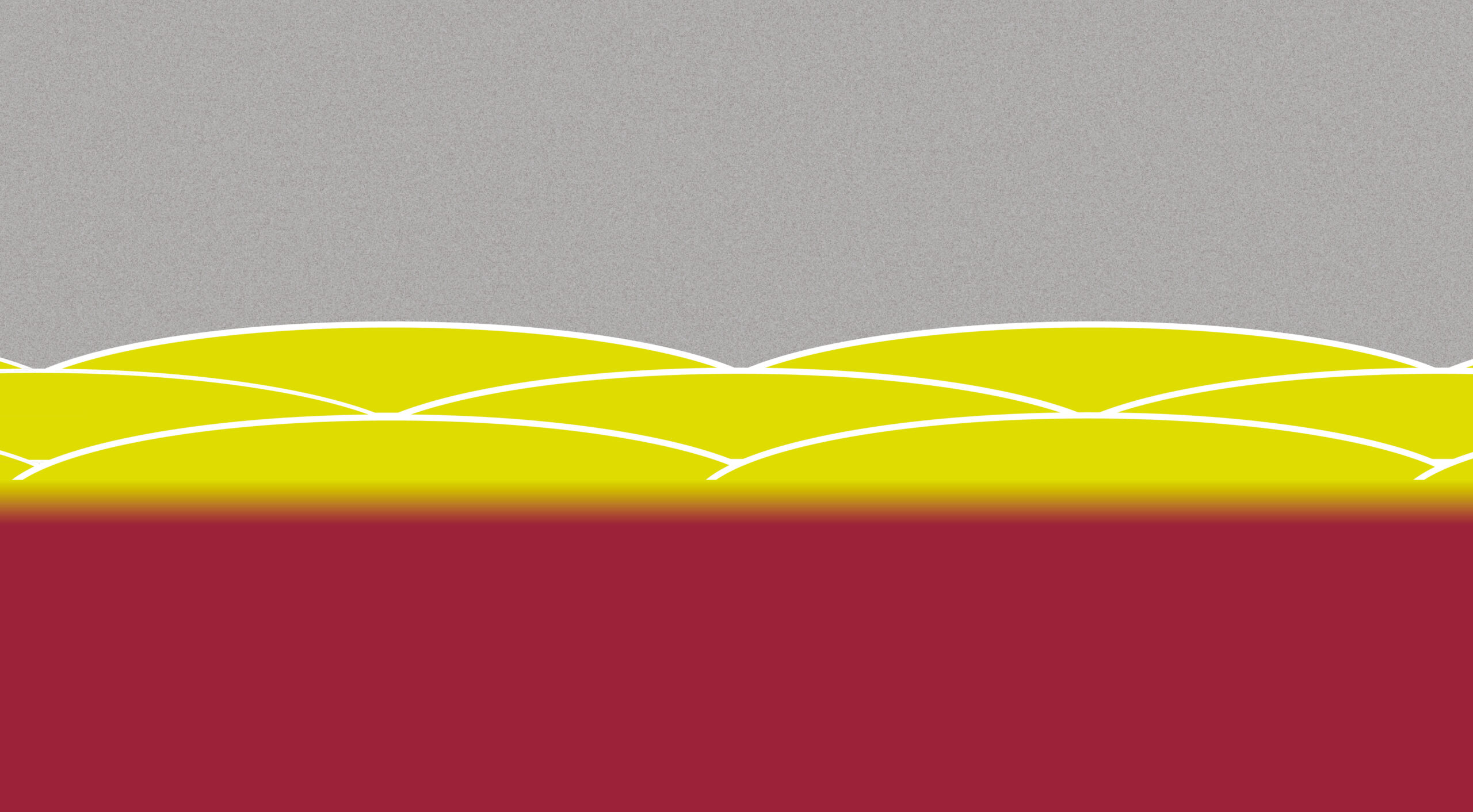

Duroxite With a Harder Baseplate

The Duroxite 101 overlay plate is also available with a Hardox 450 baseplate, as opposed to mild steel. This gives a higher performing plate compared to using a mild steel baseplate in a case where the abrasive material reaches down to the baseplate. The strength and toughness of a harder baseplate also makes the overlay plate stronger and more resistant to deformation.

STRENX® 700 E

Strenx 700 E is a structural steel with a minimum yield strength of 650-700 MPa depending on thickness. It offers superior bendability and surface quality, weldability with excellent HAZ strength and toughness and high impact toughness for good resistance to fractures.

Strenx high-strength structural steel makes your products stronger, lighter, safer, more competitive, and more sustainable.

Strenx is designed for applications where increased structural strength and reduced weight are key competitive factors. Payload and capacities are limited by equipment weight, especially in digging, material handling and mining industries. Strenx allows for stronger designs from lighter parts, making it well suited for the frame and body of loaders and excavators, the base structure of attachments and the structure of haul truck beds. Strenx equals more competitive and sustainable products – buckets that coop more material, trucks that haul more payload and equipment that uses less fuel.

| Product | Thickness Range (in) | Typical Hardness (HBW) |

|---|---|---|

| Strenx 700 | 1/8" - 6" | 650 - 700 |

Armox®

Armox “bullet-proof” armor plate steel is widely used for the protection of people and valuables in all kinds of environments all over the world.

It can withstand extreme forces from piercing objects hitting the steel at high speed, as well as having the toughness needed to resist shock forces.

| Product | Thickness Range (in) | Typical Hardness (HBW) |

|---|---|---|

| Armox 500T | 1/8" - 3" | 480-540 |