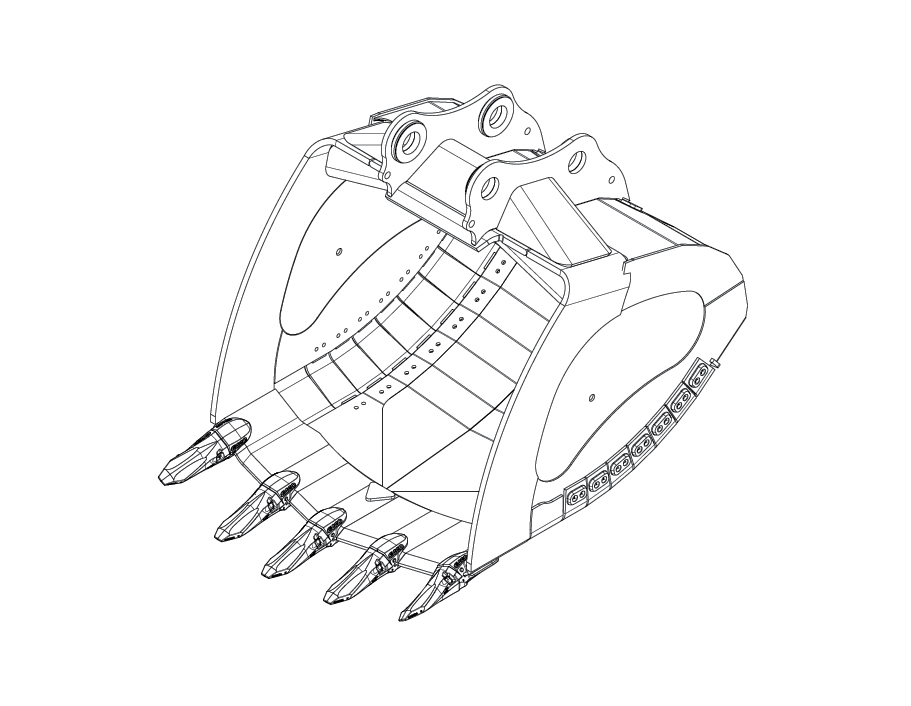

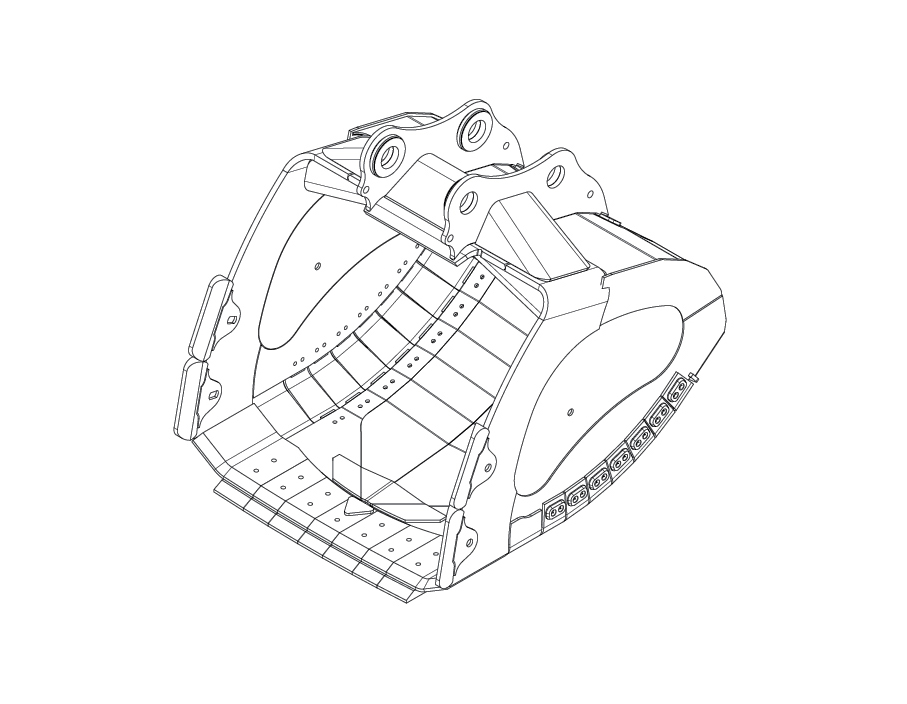

BHB SERIES

The XMOR BHB backhoe buckets target large size excavators where increased productivity in digging adds value to the process. The low weight of the buckets enables increased payload of 10-20% without increasing excavator suspended load.

The XMOR BHB-series comes with multiple patented- and design protected features.

Hardox 450 and Hardox 500 Tuf in the design allows for reduced plate thickness and better wear life

Optimized welding parameters and consumables for Hardox wear plate giving high quality welds

New beam design (patent pending) reduces weight and enables unmatched structural integrity

Less downtime is achieved by replacing traditional weld-on heel shrouds with patented mechanically attached heel segments

Inverted keel (patent pending) reduces wear on the bottom of the bucket, enabling function without heavy wear package underneath

Round smooth surfaces and a design that flex help to reduce carry back

XMOR buckets showing a man for size reference. Smallest to largest. BHB 50, BHB 60, BHB 70, BHB 80, BHB 90, BHB 100, BHB 120

Applications & Environments

Each model size targets 3 different material densities up to 2530, 2780 and 3030 lbs/CuYd. The buckets target a variety of applications within quarry industry as bulk earthworks, sand, gravel, coal stripping and blasted rock up to 20”.

Recommended configuration for different applications. Lip, GET and shrouds system is customer choice.

Non-Abrasive Rock

Spade Cutting Edge

Abrasive Rock

Spade Cutting Edge

Bulk Earthworks

Spade, Straight, Other

Abrasive Sand/Gravel

Straight Bolt-O

| Profile | BHB 50 | BHB 60 | BHB 70 | BHB 80 | BHB 90 | BHB 100 | BHB 120 |

|---|---|---|---|---|---|---|---|

| Suspended Load (lbs) | 16800– 19200 | 16800– 19200 | 20200– 23000 | 25900– 29500 | 29600– 33700 | 33600– 38200 | 38800– 44300 |

| Density (lbs/CuYd) | 2530–3030 | 2530–3030 | 2530–3030 | 2530–3030 | 2530–3030 | 2530–3030 | 2530–3030 |

| Volume (CuYd) | 3.5-4.5 | 4.2-5.3 | 4.9-6.1 | 6.4-8.0 | 7.4-9.1 | 8.4-10.3 | 10.0-12.0 |

| Bucket Weight (lbs) | 3660-4200 | 4450-5060 | 5930-6730 | 7310-8200 | 8230-9140 | 9450-10460 | 10470-11580 |

| Bucket Width (inches) | 61-77 | 63-79 | 69-85 | 73-89 | 77-93 | 81-97 | 85-101 |

| Tip to Pin (inches) | 77 | 83 | 89 | 94 | 100 | 104 | 110 |

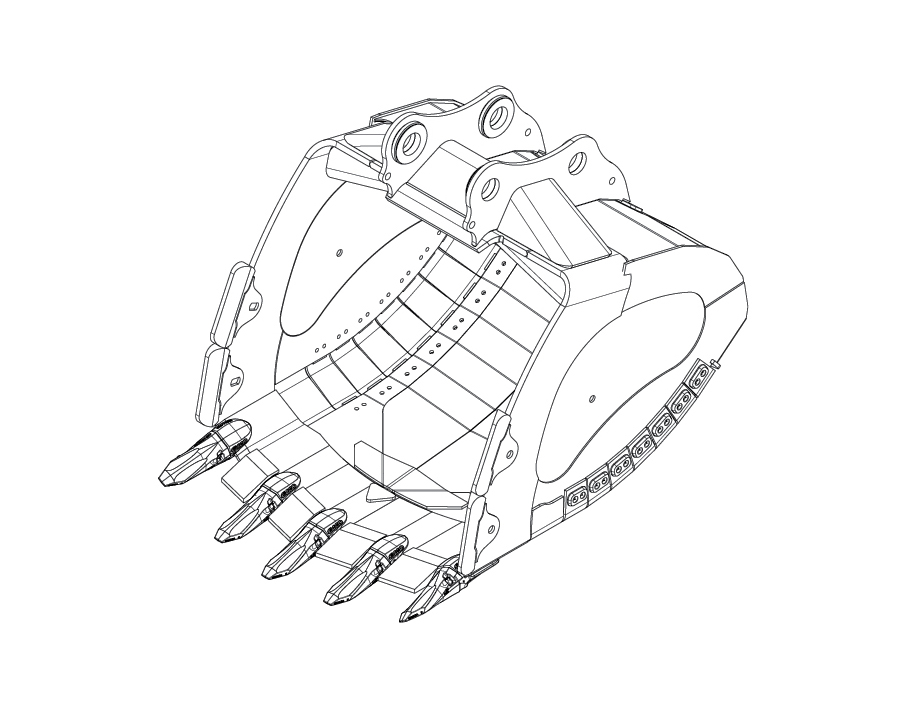

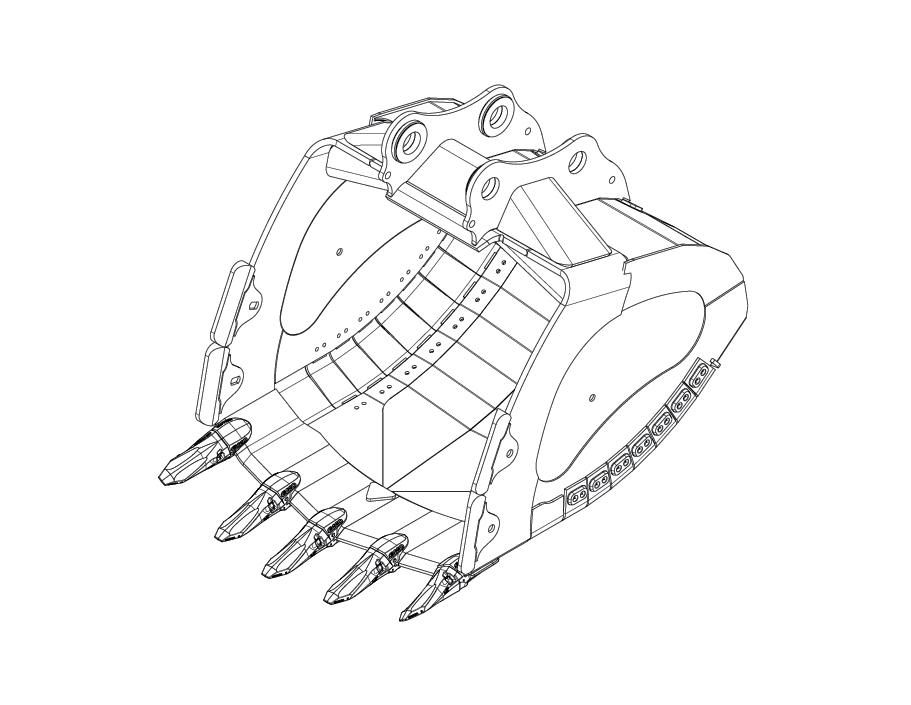

BHC SERIES – A Class of Its Own

Built to give up to 15% higher payload capacity compared to a conventional bucket. This bucket targets large-size excavators between 80 and 300 tons where increased productivity in digging adds value to the process.

High productivity buckets for tough mining conditions

XMOR BHC buckets have the necessary strength for tearing out blast footings, loading trucks and crushers with blasted rock and other heavy-duty operations such as bulk earthworks and coal stripping. The reduced weight of the bucket allows for more payload without increasing suspended load.

Performance

XMOR BHC buckets are designed for high productivity when working with rock, overburden material, sand and gravel, coal, clay and bulk earthworks.

Lower weight

The increased loading capacity of XMOR® BHC buckets is the result of reduced weight, which in turn is the result of optimizing every part for durability.

Increased uptime

XMOR BHC buckets use bolted heel segments instead of welded which means heel segment replacements can be performed in hours instead of days. Welding the heel segments on is also an option for harsher conditions.

Productivity in every detail

The XMOR BHC buckets are designed from the ground up for high productivity and long service life. They come with a number of innovative features that have approved and pending patents and design patents.

Inverted Keel

A proven and unique XMOR feature serving the dual purpose of distributing the material smoothly inside the bucket and keeping the external plate away from the material, thus reducing wear.

Flat Cutting Edge

The flat Cutting Edge accommodates various GET options for protection against rock and wear.

Cavity Corner

The Cavity Corner reduces the weight by avoiding the traditional doubling of material. The cavity is covered by our Mechanical Heel Shrouds.

Mechanical Heel Shrouds

Being mechanically attached, these heel shrouds reduce maintenance and downtime. Our Mechanical Heel Shrouds cover the Cavity Corner.

Mechanical Wing Shroud

Attached with bolts, these Mechanical Wing Shrouds are designed to fit the curved edge and protect the weld point of the cutting edge. They are reversible.

Head Beam

The teardrop-shaped Head Beam provides structural integrity and allows the main bucket to be built separately.

Keel Saddle

Keel Saddle is an optional liner plate which adds protection to the front of the Inverted Keel.

SSAB products

All of this made possible by taking optimal advantage of the qualities of Hardox wear plate and Strenx performance steel from SSAB.

Material density 2520 lbs/CuYd

| Profile | BHC 80 | BHC 90 | BHC 100 | BHC 120 | BHC 150 | BHC 200 | BHC 250 | BHC 300 |

|---|---|---|---|---|---|---|---|---|

| Suspended Load (lbs) | 29035 | 35737 19200 | 40786 23000 | 45129 29500 | 51103 33700 | 76059 | 94799 | 110363 |

| Volume (CuYd) | 8.08 | 9.94 | 11.05 | 12.07 | 13.16 | 20.57 | 25.8 | 30.11 |

| Bucket Weight (lbs) | 8598 | 10397 | 12824 | 14593 | 17835 | 24030 | 295542 | 34216 |

| Bucket Width (inches) | 85 | 95 | 100 | 108 | 112 | 118 | 132 | 140 |

| Excavator Size (lbs) | 160000- 180000 | 180000- 200000 | 200000- 260000 | 240000- 300000 | 300000- 360000 | 360000- 460000 | 460000- 560000 | 560000- 680000 |

Material density 3030 lbs/CuYd

| Profile | BHC 80 | BHC 90 | BHC 100 | BHC 120 | BHC 150 | BHC 200 | BHC 250 | BHC 300 |

|---|---|---|---|---|---|---|---|---|

| Suspended Load (lbs) | 29035 | 35737 19200 | 40786 23000 | 45129 29500 | 51103 33700 | 76059 | 94799 | 110363 |

| Volume (CuYd) | 6.74 | 8.36 | 9.28 | 10.1 | 11.54 | 17.21 | 21.58 | 25.18 |

| Bucket Weight (lbs) | 8201 | 9903 | 12214 | 13898 | 16063 | 22884 | 28131 | 32584 |

| Bucket Width (inches) | 81 | 91 | 97 | 104 | 108 | 114 | 129 | 136 |

| Excavator Size (lbs) | 160000- 180000 | 180000- 200000 | 200000- 260000 | 240000- 300000 | 300000- 360000 | 360000- 460000 | 460000- 560000 | 560000- 680000 |