diverseindustries we serve

Reaching Around the Globe

Specializing in heavy equipment wear parts, steel custom fabrication and welding or hydraulic repair, Cutting Edge Supply supports many of today’s integral industries including mining, construction, material processing, waste and recycling, agriculture, food processing and processing, oil and refinery, and more.

MINING

Ground Engaging Tools such as edges, teeth, corner guards, wear shrouds, and lip systems are essential for most mining operations.

We provide one of the largest selections of G.E.T. in North America with vast offerings from the major proprietary and after-market manufacturers, including hammerless tooth systems and bolt-on wear solutions.

However, Cutting Edge Supply also offers much more to our customers in the mining industry, including custom fabrication, wear management, pins and hydraulic cylinder exchange or repair, dipper wear packages, haul truck bed liners and repair, large bucket and dipper shovel repair, and slurry pumps sales and parts.

CONSTRUCTION

As both a parts manufacturer and dealer, Cutting Edge Supply offers wear products designed for all types of construction heavy equipment.

Our goal is to provide quality parts in a timely manner and at a fair price to the earth moving and land development industries. We specialize in parts and repair for backhoes, dozers, dump trucks, loaders, excavators, trenchers and scrapers.

We offer wear parts and replacement parts from the smallest walk-behind machines to the largest wheel loaders and excavators.

MATERIAL PROCESSING

Cutting Edge Supply offers many products suited for all types of material processing operations including ready mix, asphalt batch plants, rock quarry, sand and gravel and other materials.

We provide wear parts for a variety of plant needs, including clam bucket and dragline parts and repair, drum dryer liners and flights, drive chain and incline elevator chain, as well as sprockets and liners.

AGRICULTURE, FOOD PRODUCTION & PROCESSING

Cutting Edge Supply provides a range of wear and replacement parts for the agriculture and food processing industry including grader blades, cutting edges, digging teeth and shanks, backhoe attachments, carbide wear bars, ripper plow shanks and teeth with 700+ Brinell hardness wear caps, as well as chromed tiller tines and box-scraper parts.

Additionally, our Chrome Craft division can apply hard chrome to sheer blades or harvesting weeder bars for extended wear life, and are experts in rebuilding John Deere tractor axle shafts.

Chrome Craft also remanufactures many parts for food processing plants, including package sealing machine parts, votator tubes, heat exchanger tubes, can packing guides, can seamer parts, can making machine parts, vacuum filler parts, syrup fillers, dicing machines parts, milk homogenizer pistons, all types of cylinders, freezer barrels, dashers, mutators, fruit feeders, and more.

OIL FIELD AND REFINERY

Chrome Craft has long been a quality source for hard chrome and precision machining for oil field and refinery parts. We can recondition a large assortment of parts back to standard dimensions.

This includes the remanufacture of polished rods, pump shafts, turbine shafts, and a variety of other mechanical parts.

Chrome Craft also offers automatic submerged-arc welding, automatic bore welding, and machining and honing. We can provide new threads, new keyways, new splines and rebuild bearing and seal areas back to original specification for many different parts.

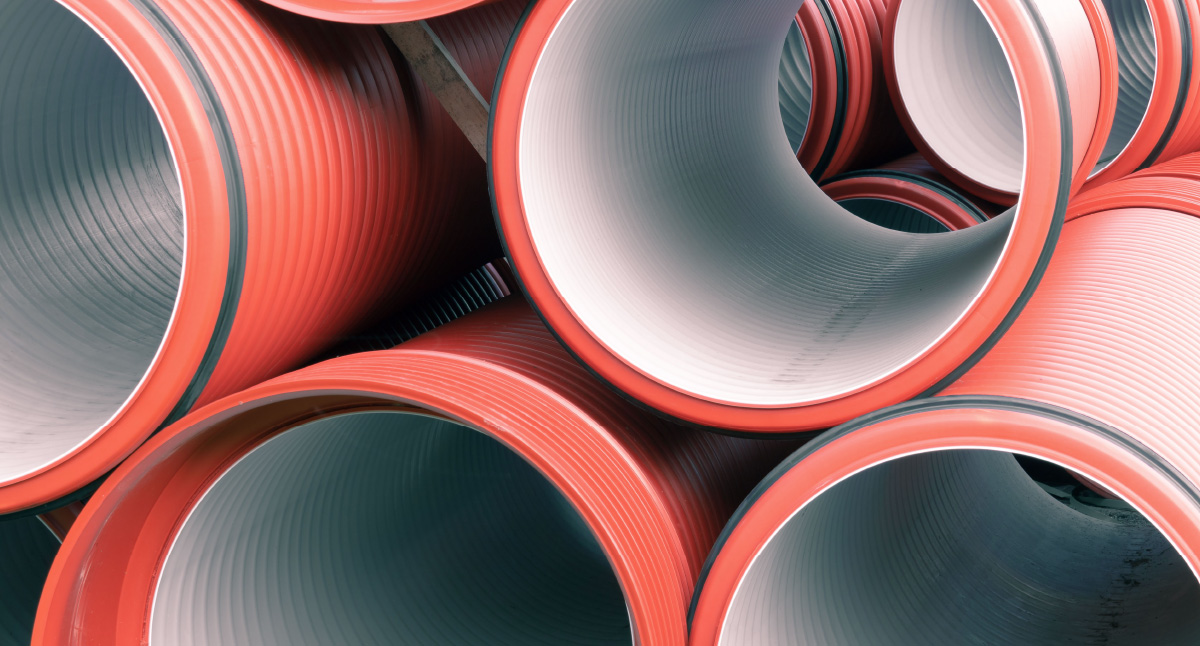

PLASTIC EXTRUSION

How can plastic wear out metal parts?

Just ask the tool and die department at any plastic extrusion company. Or come to Chrome Craft when we receive another shipment of dies, spiders, mandrels, sizing sleeves, pins, gauges, or other pieces to be hard chromed. Plating these parts requires true craftsmanship. From anode building to plating to final polishing, the skill of our plating technicians is evident in the quality of their finished products. Producers of plastic pipe rely on us to stretch the time between costly maintenance shutdowns.