Turn to Cutting Edge Supply

for the highest quality and top-performing screening media and accessories.

We offer custom made-to-order wire and punch plate screens along with crown bar covers (rubber or upgraded urethane) and side-tension rails, and we stock a variety of rubber and urethane screens for all mobile and stationary equipment. Our products are designed to handle the wide range of applications across the aggregate industry, and our expert sales team is here to help you determine the proper screening media to maximize productivity.

Custom Made-to-Order

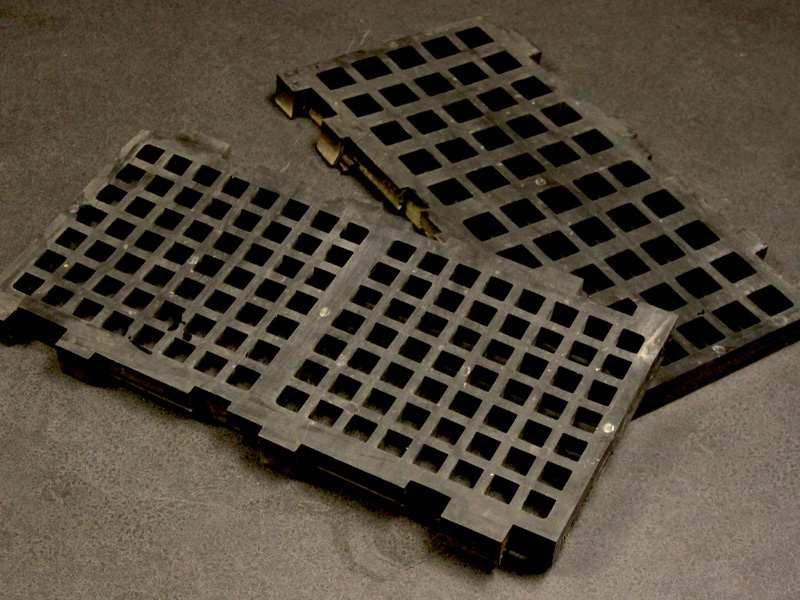

Custom Made-to-Order Punch Screens

Cutting Edge Supply manufactures punch plates for various screening applications. These include hooked screens for scalping screening plants, screens for trommel drums in rolled or flat sections, grinder and mulcher screens for green waste processing, and bucket skins for sifter screening buckets.

Other manufacturers have limitations to the hardness a punch plate can be—typically maxing out at 200 Brinell hardness. Because we cut our pattern opposed to using a traditional punch press, our screens are available in a variety of thicknesses of super tough Hardox 450 and Hardox 500 Tuf materials up to 500 Brinell. We can plasma cut or waterjet cut the pattern depending on the required tolerances and also precision drill for bolt-down screen applications.

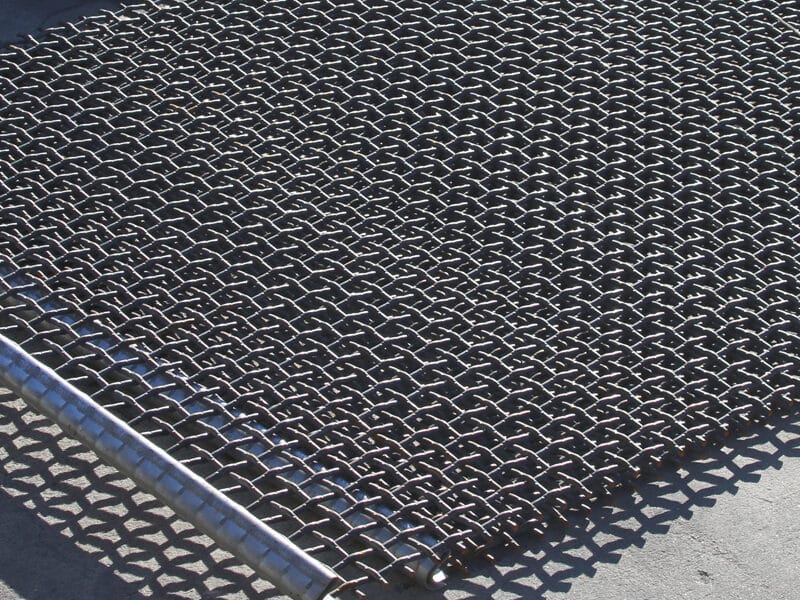

Custom Made-to-Order Wire Screens

We have a fully operational production plant to manage custom made-to-order wire screens of any dimensions. We source our wire materials from Metso, offering either Superloy or Ultraloy.

Superloy offers a combination of excellent fatigue resistance coupled with good abrasion resistance. This mid-range wire can go head-to-head against most competitor’s high-carbon wire.

Metso’s premium wire offering, Ultraloy, has the optimum combination of strength, ductility and abrasion resistance. These properties combined with advanced manufacturing processes deliver a product that will produce up to 30% increase in wear life in even the most demanding applications.

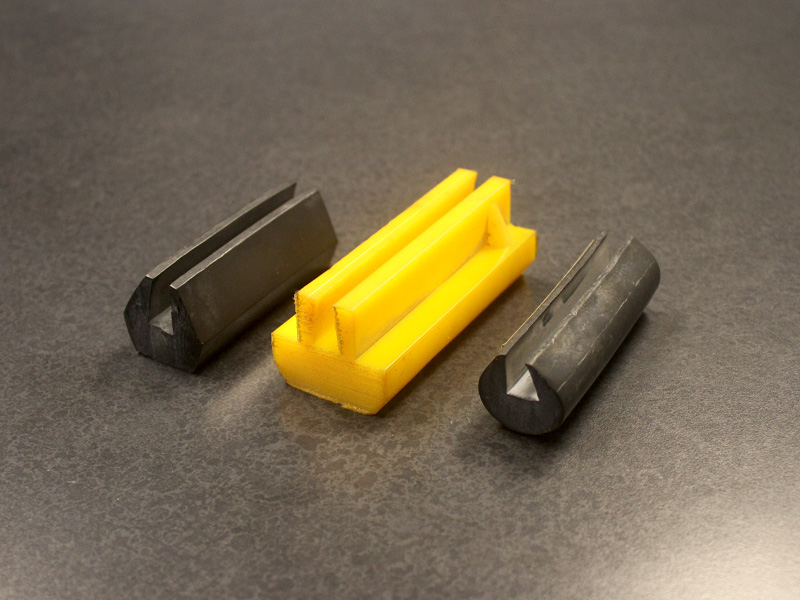

In addition, we supply Crown Bar Covers in either rubber or urethane to protect the crown rails, as well as side-tension rails and hardware when required by your machine.

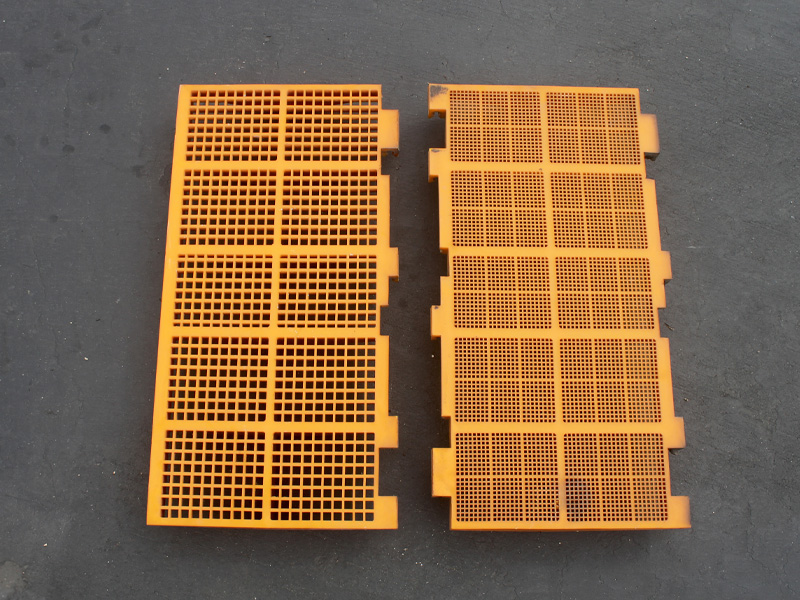

Rubber & Urethane Screens & Side Liners

We stock Durex rubber and urethane screen, both tension and modular, as well as side liners.

Not sure what you need? Don’t sweat it! Our expert sales team can help you identify the correct replacement screen to ensure optimized throughput.

We’ll need some basic information, including screening machine make and model, application, dimension, size of the openings and type of latching mechanism.

HOW TO ORDER

Our sales team strives to consistently provide superior customer service through each step of the ordering process, including helping you to quickly identify the parts you need, providing a price estimate, and advising you on additional wear part protection upgrades that can save you time and money in the long run. They will also do everything they can to expedite your order and reduce downtime.

Call

(800) 949-9014

to get the ball rolling.

delivery

Our normal and free delivery radius is within 150 miles from any of our six locations. We can also ship nationwide and will work to find you the best option.

PAYMENT METHODS

We accept American Express, Mastercard, Visa and check.