Cutting Edge Crushing Parts

Turn to Cutting Edge Supply for an extensive line of replacement parts for all major makes and models of crushing equipment — from the smallest to the largest-sized cone, gyratory, impact and jaw crushers.

We stock products from premium brands including Durex, ESCO, Excel Foundry and Spokane Industries, as well as offer custom made-to-order parts from our own in-house production plant.

We offer stationary & moving jaw dies, cheek plates, wedges and toggle plates, cone liners, cone mantles, mantle torch rings, gyratory mantles, spider liners, impeller bars, impact liners, side liners, grizzly bars and assemblies, and more.

All products feature high-quality materials from abrasive-resistant steels to manganese, hi-chromium or ceramic composite castings to rubber or custom wear-resistant urethane solutions. These parts are designed to meet heavy-duty demands, providing superior equipment protection during the reduction and sizing of aggregates for construction, mining and material processing applications.

products we carry

-

Jaw Dies: Stationary & Moving

- ESCO. View Catalog.

-

Cheek Plates

- Custom Made-to-Order

- Hardox 450/500

-

Spares (Wedges, Toggle Plates)

- ESCO. View Catalog.

- Cutting Edge Supply also offers Made-to-Order

brands we carry

Cutting Edge Supply

CALL FOR INFO

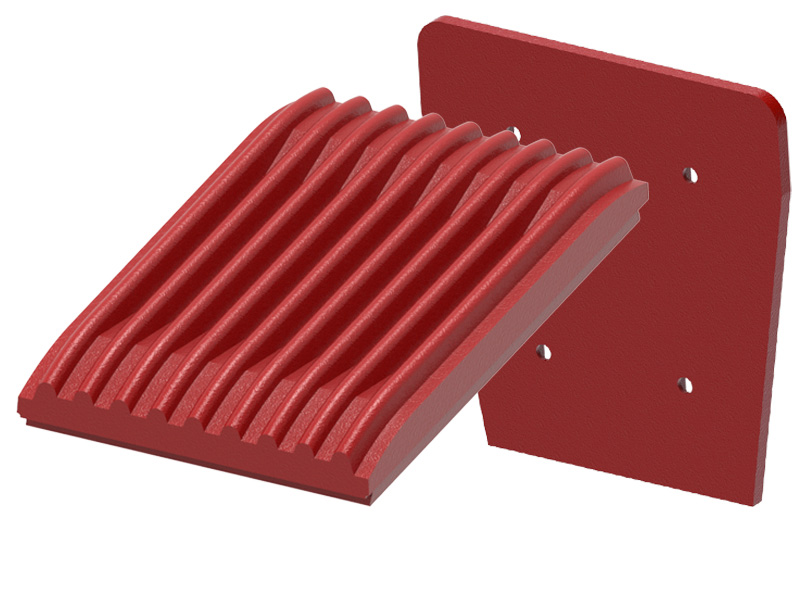

Durex (Molded Rubber & Urethane)

Esco (Jaw Parts, Cone Parts & Gyratory Parts)

Excel Foundry (Cone crusher parts)

Spokane Industries (Impact Crusher HSI/VSI)

Premium Materials

SSAB Hardox Steel

For Cutting Edge Supply made-to-order Cheek Plates, we use Hardox 450 or 500 steel — the toughest abrasive-resistant steel on the planet. Additionally, we offer Tungsten Carbide Embedding, which adds extremely hard TC granules to the parent material in the most vulnerable wear areas, thus improving performance and prolonging the life of your product.

Spokane Industries: Hi-Chromium & Ceramic Castings

Spokane Industries Si-Tec materials are a patented ceramic composite technology that creates casting with unequaled abrasion resistance and longer wear life, while maintaining the easy installation of traditional cast wear parts. Customers have seen 1.5 to 4 times more wear life in a variety of applications for Impact Crusher parts.

ESCO Manganese Alloy Castings

Superior ESCO manganese alloy castings are the result of a century of metallurgical experience and commitment to unsurpassed quality. ESCO has six grades of manganese alloy, each with specific field –tested applications to optimize the performance of your Jaw, Cone, or Gyratory crusher mantles and liners.

HOW TO ORDER

Our sales team strives to consistently provide superior customer service through each step of the ordering process, including helping you to quickly identify the parts you need, providing a price estimate, and advising you on additional wear part protection upgrades that can save you time and money in the long run. They will also do everything they can to expedite your order and reduce downtime.

Call

(800) 949-9014

to get the ball rolling.

delivery

Our normal and free delivery radius is within 150 miles from any of our six locations. We can also ship nationwide and work to find you the best option.

PAYMENT METHODS

We accept American Express, Mastercard, Visa and check.