servicesPLATE CUTTING

PLATE CUTTING

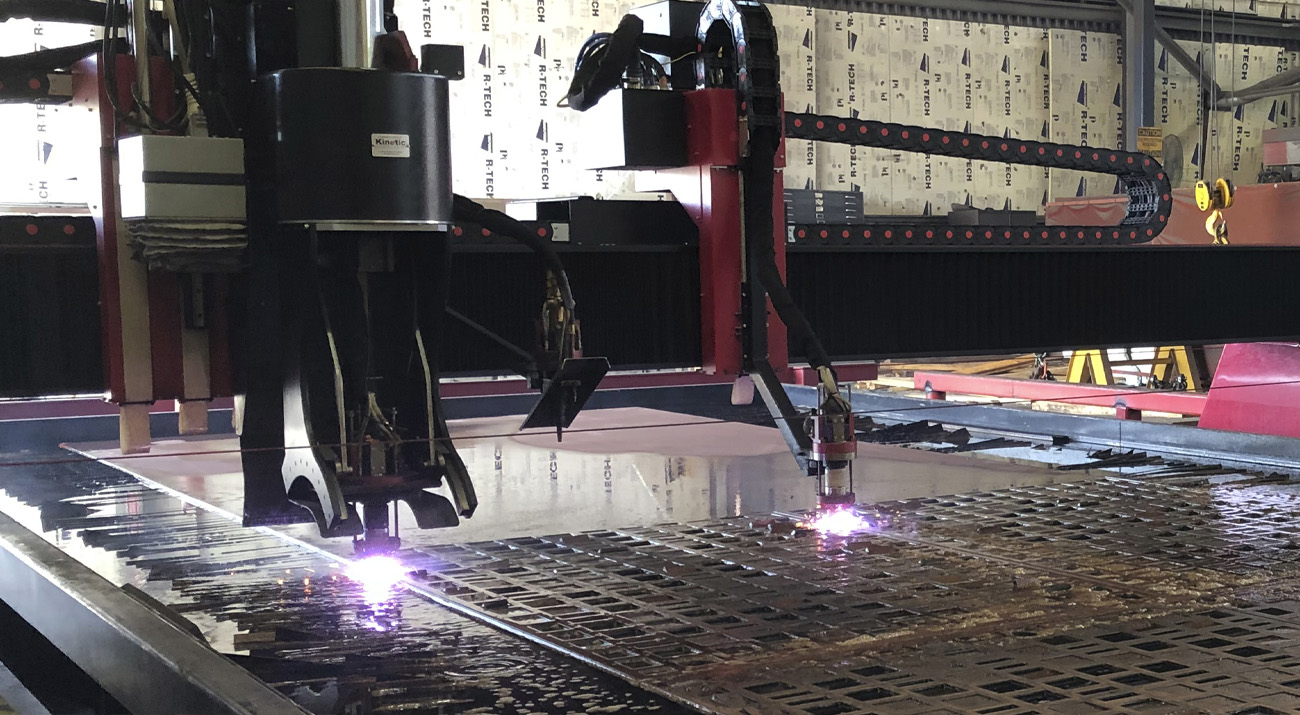

Equipped with state-of-the-art cutting tables, our shop utilizes heat applied plasma and oxy-torch, as well as waterjet for plate cutting (flat cuts, beveling and rough holes). Our machines can handle steel of all grades, and up to 8”-thick steel.

Kinetic K5000XMC Plasma Cutting System

Kinetic’s K5000xmc is one of the most modern cutting systems available. Built for heavy-duty combination plasma cutting, oxy-fuel cutting and milling and even some machining, it can handle up to 3”-thick steel. This system features a large 14’ x 50’ table, submergible bed and 24 tool stations with auto tool change out, allowing us to do an entire cutting edge on this one machine. It will cut the outside shape, bevel the edges, and then switch tools to machine in the holes.

Kinetic K2500 Plasma Cutting System

The K2500 delivers renowned Kinetic accuracy and efficiency in a medium-duty plasma cutting system. Its capabilities include plasma cutting, oxy-fuel cutting, beveling and multi-torch cutting. Our system features a large 13’ x 90’ table with a submersible bed, allowing us to preload multiple longer sheets for improved speed. This system also features four configurable stations on the main torch carriage.

Messer Titan III Plasma Cutting System

This heavy-duty CNC flame cutting table has both oxy and plasma torch capabilities and is utilized for cutting our thickest plates of steel. It can handle 8’ x 24’ sheets of steel, and up to 8” thick.

Waterjet Cutting

We also offer “cold cutting” via precision waterjet. Although a slower process, waterjet cutting provides a cleaner edge and a tighter tolerance than our other heat-applied processes.