servicesCUSTOM ENGINEERING SOLUTIONS & FABRICATION

IN-HOUSE EXPERTISE & STATE-OF-THE-ART MACHINERY

Using the latest technology in computerized CAD systems, our in-house drafting and engineering team can help save you time and money with sophisticated solutions for your business needs.

We have over 60,000 drawings on file from past orders and stock parts, and our custom steel fabrication capabilities include building buckets, lips, edges, punch screens and much more from scratch. We are also fully loaded with state-of-the-art machinery to cut and form materials — from the thinnest gauge metals up to 6”-thick steel plates.

Additionally, our Chrome Craft division has an extensive library of drawings on file, as well as the expertise and machinery to either transform your worn hard chrome parts back to their original specs or build a custom part completely from scratch including pins, valve blocks, valve spools, axle housings, cylinder rods, drive shafts, connector blocks and trunnions.

Our Work

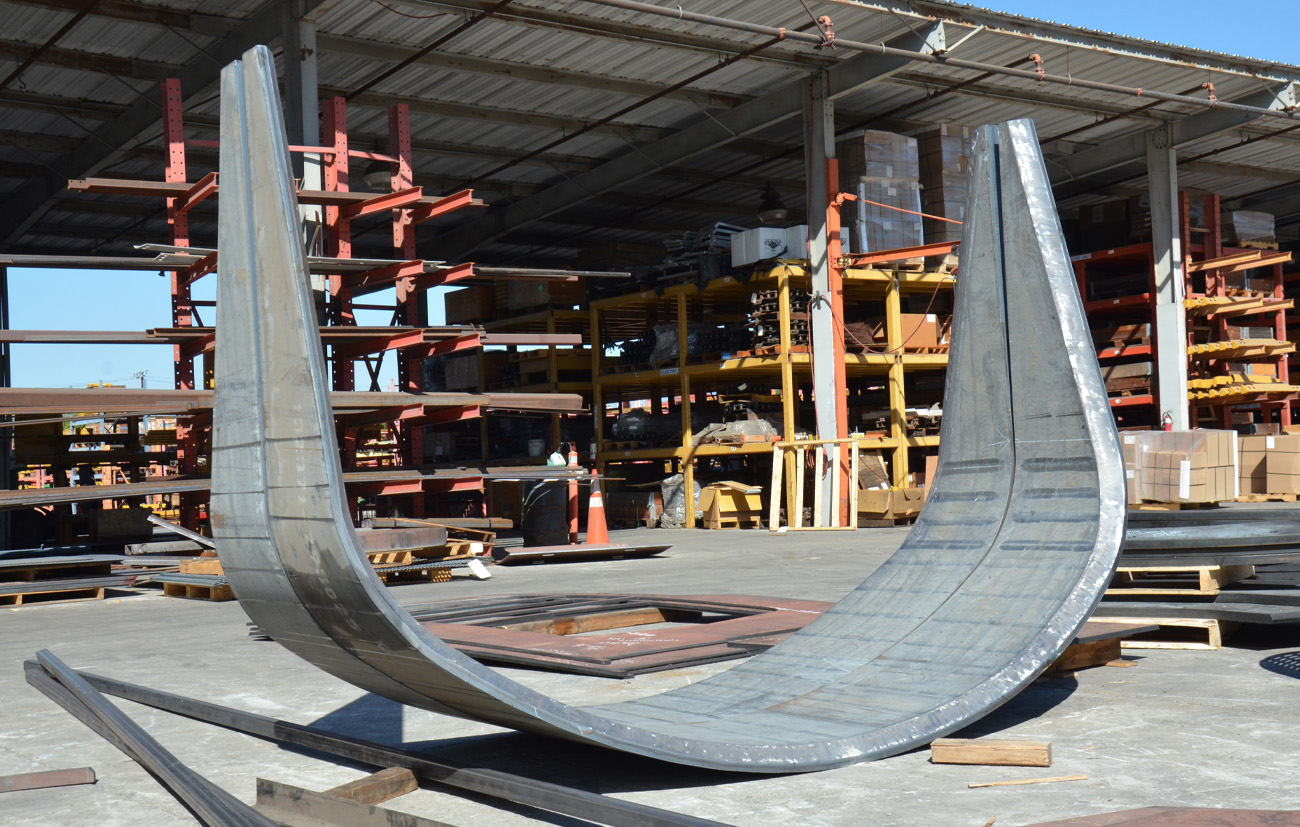

Cyclone Silo for Material Processing Plant

A break from the norm, Cutting Edge Supply took on this custom fabricated cyclone silo order for a material processing plant, featuring Strenx 700 for the base material, Hardox 450 lining and Duroxite wear parts.

Designed and built at our headquarters in Colton, California, the parts were then delivered by truck and assembled at the plant site.

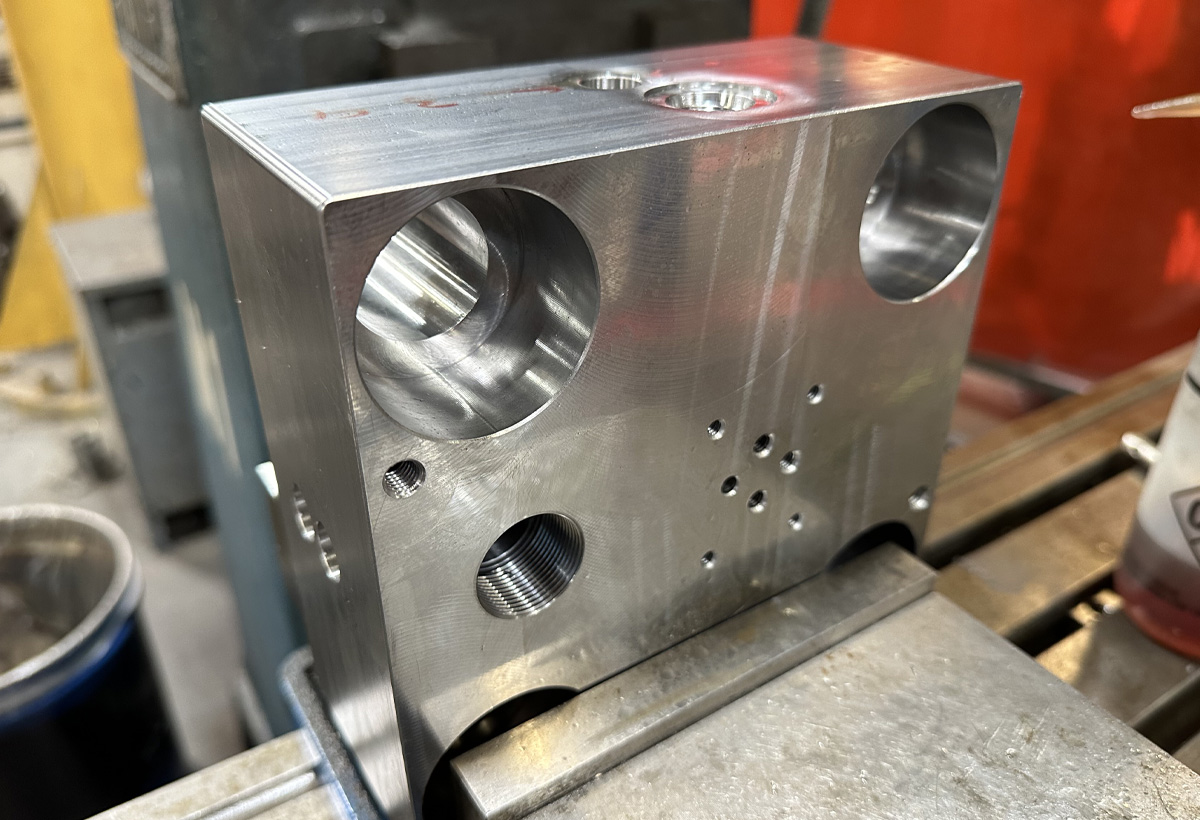

Hydraulic Valve Block

Our Chrome Craft team took on this custom fabricated conveyor shredder valve block, which controls the fluid flow in and out of the machine’s hydraulic cylinder units. This part is normally made elsewhere for our client from cast steel, but they were unable to get what they needed turned around in time. Instead, they asked us to recreate it by custom machining a solid chunk of structural alloy steel. It was a very complex project, with many intricacies inside the valve’s intersecting holes. Most of these holes were done on our precision CNC machine, but this final

deep orifice had to be hand-tapped.

CAT 994 Bucket Restoration

This Caterpillar 994H loader bucket was originally custom built in-house by our team in 2015.

Thanks to skilled craftsmanship and the use of high quality Hardox steel, this bucket has outperformed and outlasted its OEM counterparts to deliver increased wear life, dependability, and value to the customer. After years in service with an Arizona mining property, it was time to come home in early 2023 for a complete refurbishment, again using Hardox materials.