How to Pre-Heat Steel

In warmer west coast or southern climates, preheating steel might not always be necessary especially during the summer months. In wintertime, however, temperatures often fall below the recommended levels of plate welding and cutting even in these areas. And for many locations across the United States, winter means freezing temperatures in addition to average temperatures lower than the recommended temperature for welding and cutting. Preheating steel is absolutely necessary when working in weather below the recommended temperature to ensure the lowest possibility of cracking and a better chance of strong, good-quality welds.

Preheating generally refers to raising the temperature of the parent steel above 170°F (76.67°C). It is important to note that while many of our offered materials (Hardox 400/450) require “no pre-heating” on thicknesses below 2 inches, this should be taken to mean “no-preheating above room temperature” (68°F/20°C or above). If a plate is left in a temperature controlled shop, there is no doubt that the plate will be around this “safe to work with” temperature range.

However, since a majority of the plate is stored outdoors overnight, some heating will be needed during the winter months to bring the plate up to a safe working temperature. If a plate is left out in the cold and you try to cut a section for use, the plate will crack. However, a few minutes of warming can result in better cutting results and eliminate material cracking. When temperatures drop, be sure to factor into your welding estimates the time needed to preheat and post-heat your weld joints.

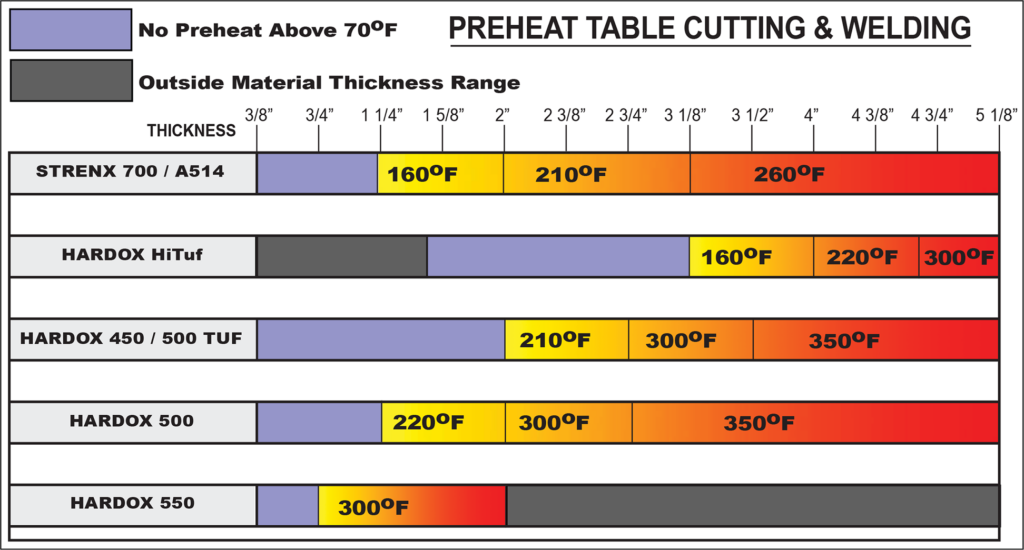

Note: When using the preheat chart be sure to combine your plate thickness that you’re welding together as shown at left.

Chart Information: STRENX 700 – 3/8″ to 1 1/4″ No Preheat above 70°F. 1 1/4″ to 2″ 160°F. 2″ to 3 1/8″ 210°F. 3 1/8″ to 5 1/8″ 260°F. HARDOX HiTuf – 3/8″ to 1 5/8″ Outside Material Thickness Range. 1 5/8″ to 3 1/8″ No Preheat above 70°F. 3 1/8″ to 4″ 160°F. 4″ to 4 3/4″ 220°F. 4 3/4″ 5 1/8″ 300°F. HARDOX 450/500 TUF – 3/8″ to 2″ No Preheat above 70°F. 2″ to 2 3/4″ 210°F. 2 3/4″ to 3 1/2″ 300°F. 3 1/2″ to 5 1/8″ 350°F. HARDOX 500 – 3/8″ to 1 1/4″ No Preheat above 70°F. 1 1/4″ to 2″ 220°F. 2″ to 2 3/4″ 300°F. 2 3/4″ to 5 1/8″ 350°F. HARDOX 550 – 3/8″ to 3/4″ No Preheat above 70°F. 3/4″ to 2″ 300°F. 2″ to 5 1/8″ Outside Material Thickness Range.