servicesour capabilities

Your West Coast Wear Parts & Service Specialists

Cutting Edge Supply is a one-stop shop for specialized steel and chrome wear parts and services across the mining, construction and material processing industries.

A well-oiled operation with more than 70 years of experience under our belt, we offer a wide-range of capabilities including custom steel fabrication, tungsten carbide embedding, hard chrome plating, and full-service welding or hydraulic repair to reduce your heavy equipment downtime.

We have an expert drafting and engineering department that provides innovative and out-of-the box cost-saving solutions, with workshops housing state-of-the-art machinery and a team of skilled technicians to bring their visions to reality.

Best In Class

ON-SITE INSPECTION

Equipment downtime can be devastating to your bottom line. Our experienced, knowledgeable and service-oriented sales team will evaluate your equipment on each site visit, identifying wear and tear issues before they put you out of commission.

STATE-OF-THE-ART MACHINERY

We are fully equipped with our own in-house state-of-the-art precision machines, including a multi-process plasma cutting/CNC table, the largest tonnage press brakes on the West Coast, high-capacity CNC milling stations, hard chrome tanks and more.

UNRIVALED EXPERTISE

There’s no “can’t” in our vocabulary. Time and time again, our incredibly talented team pulls off jobs no one else in the industry can. Our innovative drafting and engineering team thrives on the challenge of devising custom-tailored solutions, while our seasoned machinists, welding and hydraulic repair technicians deliver top-notch workmanship.

Services

CUSTOM ENGINEERING SOLUTIONS & FABRICATION

Using the latest technology in computerized CAD systems, our in-house drafting & engineering team can help save you time and money with sophisticated solutions for your business needs. We have over 60,000 drawings on file from past orders and stock parts, and our custom fabrication capabilities include building buckets, lips, edges and much more from scratch.

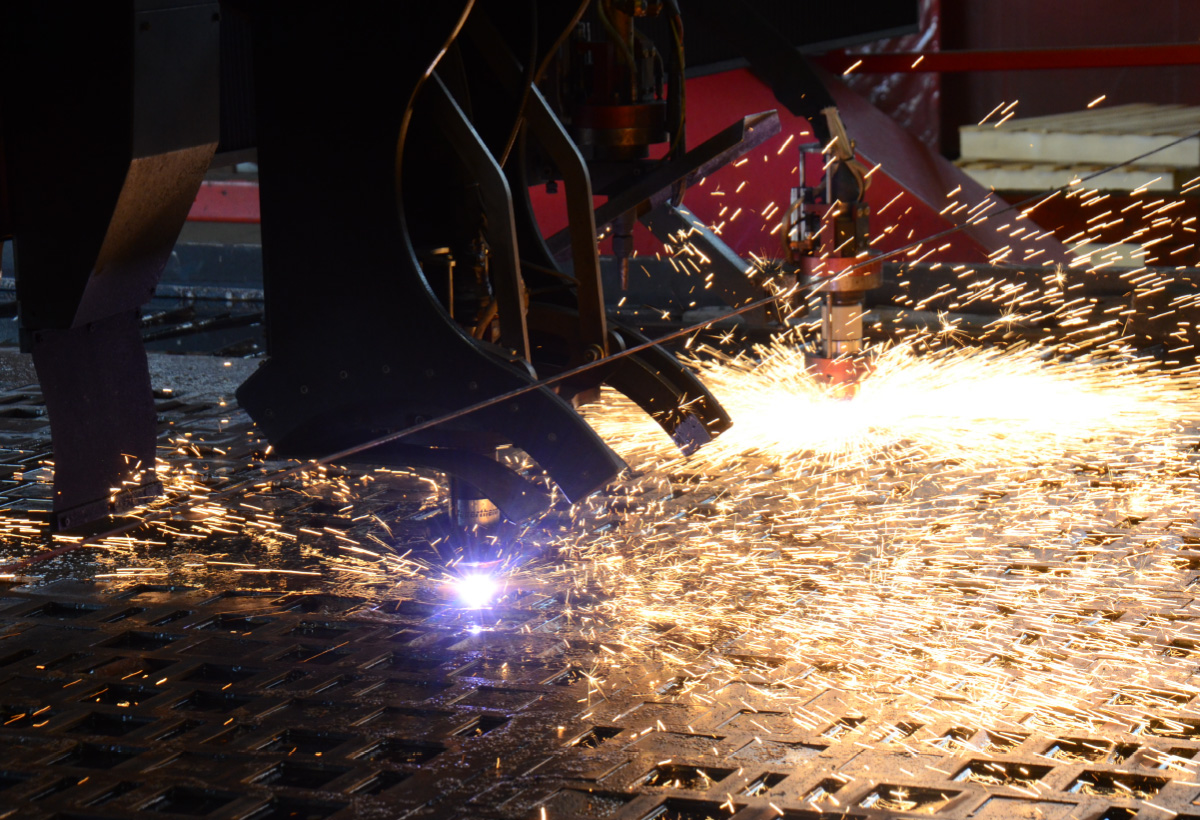

PLATE CUTTING

Equipped with state-of-the-art cutting tables including both Kinetics and Messer, our shop utilizes heat-applied plasma and oxy-torch, as well as waterjet for plate cutting — flat cuts, beveling, and rough holes. Our machines can handle steel of all grades up to 8”-thick.

PRECISION MACHINING

We are equipped on-site with heavy duty General & CNC Machining, allowing us to expedite your custom fab, remanufacture, or repair job. Our state-of-the-art machines superiorly handle CNC milling, face-milling, beveling, drilling, boring, and tapping of the hardest and strongest steels on the planet while delivering against the tightest tolerances.

FORMING

We are a steel forming powerhouse with some of the most powerful and largest press breaks in North America, capable of bending up to 4.5”-thick steel plates.

MACHINE CAPACITIES

Want to know more about our machinery? View a full rundown of the machines across our three service & repair locations.

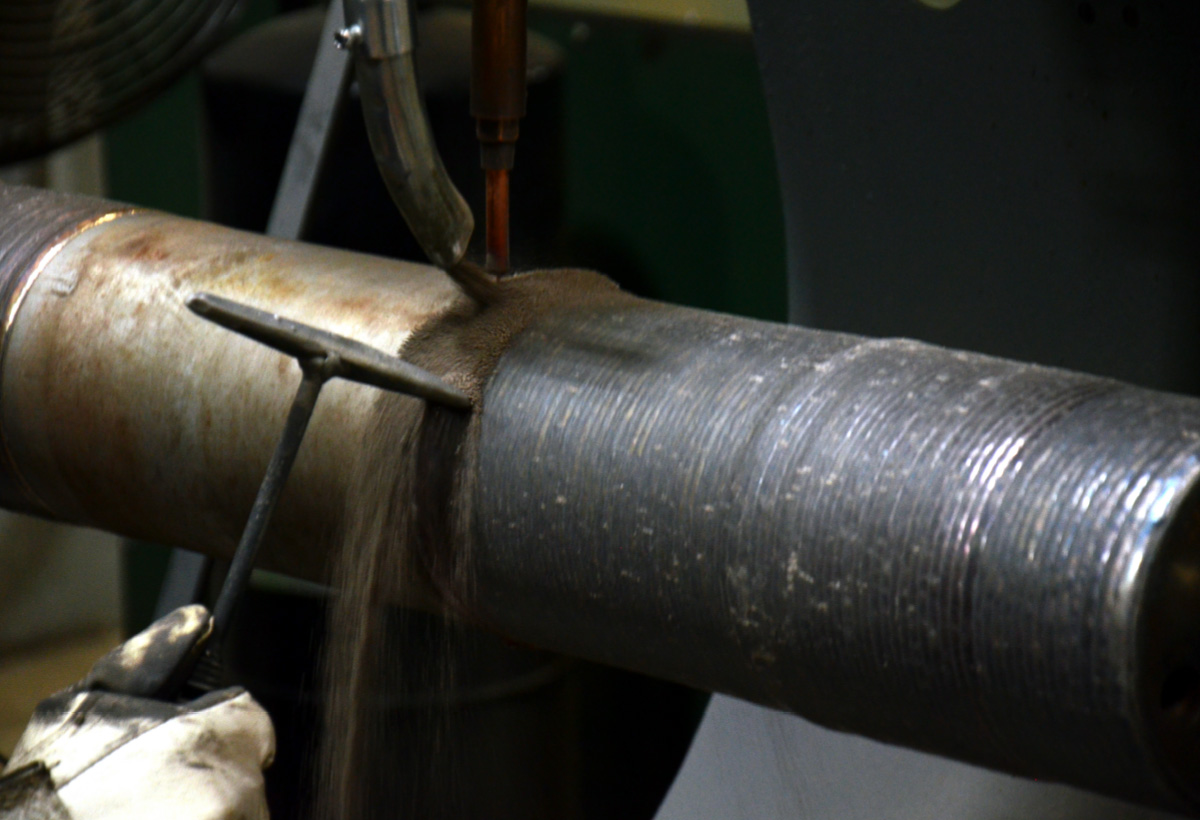

WELDING REPAIR

Our welding technicians have the expertise and skill to tackle repairs, installs, reinforcement, wear liners and lip/adapter conversions, as well as many out of the ordinary steel jobs. From welding mini excavator buckets to rehabbing the dozer liners on a D11 to the complete overhaul of massive P&H 70-yard dipper shovels, our team can handle the job.

PIN & HYDRAULIC REPAIR

Our expert hydraulic specialists at our Chrome Craft location in Sacramento test and evaluate your cylinder units to determine a recommended course of action. Our team can handle all fixes in-house — whether it’s a simple reseal job, minimal chrome and grind repair, or a complete hydraulic cylinder system rebuild/overhaul. Through the same repair shop, our team can also transform your worn OEM pins back to its original specs or make custom pins from scratch.

TUNGSTEN CARBIDE EMBEDDING

Drastically improve the longevity of your GET wear life with Tungsten Carbide Embedding. Registering just below diamond in hardness, Tungsten Carbide granules are strategically embedded into the parent material at its most vulnerable and high wear areas.

HARD CHROME PLATING

Our Chrome Craft team is well-known in the industry for their expertise in quality hard chrome plating and precision grinding. Extremely hard (up to 70 HRC) and corrosion resistant, hard chrome makes for an excellent coating for many industrial metal surfaces subject to wear, including turbine shafts, bed plates, hydraulic cylinder rods, extrusion dies, transmission shafts and much more.

FIELD SERVICE

Available on the go and where you need us! We employ an experienced repair field service crew, specializing in wear packages and repairs of mining and heavy construction equipment including cable-shovel dippers, loaders, and haul trucks, as well as maintenance and repair services for crusher and screening equipment.

Featured Project

CAT 994 Bucket Restoration

This Caterpillar 994H loader bucket was originally custom built in-house by our team in 2015.

Thanks to skilled craftsmanship and the use of high quality Hardox steel, this bucket has outperformed and outlasted its OEM counterparts to deliver increased wear life, dependability, and value to the customer. After years in service with an Arizona mining property, it was time to come home in early 2023 for a complete refurbishment, again using Hardox materials.